Extreme Filter Efficiency

The hydraulic market accepts that 80% of mechanical failures are caused by contamination in the system.

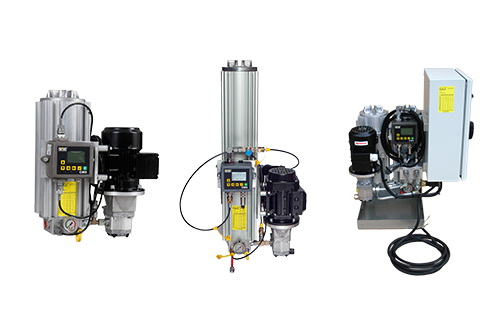

The RMF Off-Line Units attack contamination of your systems at source. In addition to solid particles, these filters are also capable of removing water from the oil. The use of RMF filters means less defects, less maintenance, and less wear and tear of the hydraulic components. The RMF Off-Line Units can be fitted to every imaginable industrial application where hydraulic or lubrication systems are present.

Water absorbing

RMF Water absorbing filters are off-line filters that use a special water absorbing spin-on as a pre-filter. The fluid is pumped through the pre-filter which removes most water and larger solid contamination, in the second stage the fluid passes through the RMF cellulose micro filter where final water removal takes place as well as solid particle removal.

Heated off-line filters

The ‘Heated unit’ is a unique progression of the Off-line filter series.

The filtration of high viscosity oils, in both hydraulic and lubrication systems, is an almost impossible task for fine filters as the thickness of these oils ‘block’ almost all normal filters.

The RMF Heated unit warms the oil in a specific manner, allowing the viscosity to be reduced to a level which will permit fine filtration without the oil being exposed to too high temperatures that could cause overheating and burning of the oil, rendering it useless.

Applications

The Air driven RMF Off-line filter units can be fitted to every imaginable industrial application where hydraulic and/or lubrication systems are present. The air motor makes the unit suitable for use in explosion hazardous areas, or areas where no electrical power is available. The standard range of Air driven Off-line filters can be utilised in reservoirs with a maximum volume of 11,000 litres.

Reseñas

No hay reseñas todavía.